Discussions about material safety in vaporizers are important — especially when high operating temperatures are involved. Recently, a user raised a thoughtful concern about TPU safety in vaporizers, questioning whether TPU is suitable for use when device temperature settings can exceed 480°F.

This question is completely reasonable. However, to evaluate material safety accurately, it’s critical to understand how a vaporizer actually works — particularly how vapor airflow cooling dramatically reduces temperature long before vapor reaches any TPU component.

At JCVAP, material selection is based on real-world thermal exposure, not just heater setpoints listed on a screen.

Heater Temperature Is Not Vapor Temperature

One of the most common misconceptions in vaporizer design is assuming that the heater temperature equals the temperature experienced by every internal component.

In reality, modern vaporizers rely on controlled airflow and staged cooling. While the heater core may reach high temperatures to efficiently extract material, vapor does not travel directly from the heater to the mouthpiece.

Instead, it passes through a carefully engineered vaporizer airflow design that reduces temperature step by step.

Stage 1: Fresh Air Mixing — The Largest Temperature Drop

The first and most significant cooling stage happens immediately during vapor generation.

As vapor forms, it is mixed with a large volume of fresh ambient air. This airflow is not incidental — it is a core part of the Pockety vapor path design.

This mixing process alone reduces vapor temperature by more than 60%, even before it leaves the heating chamber. Beyond cooling, this step also improves flavor clarity and draw smoothness.

Stage 2: Internal Airflow Cooling (10–15% Additional Reduction)

After initial mixing, vapor continues through the internal air channel.

During this stage:

Heat dissipates into surrounding structural materials

Airflow velocity prevents prolonged heat exposure

The vapor remains in constant motion, reducing thermal dwell time

This second stage contributes an additional 10–15% temperature reduction, further lowering the vapor temperature before it reaches downstream components.

Together, these two stages form the backbone of effective vapor airflow cooling.

Actual Temperature at TPU Contact Point

Thanks to multi-stage cooling, the vapor temperature at the point where it encounters TPU components is well below 130°F (≈55°C) in real-world operation.

This temperature is far within the safe operating range of the TPU grade used, demonstrating strong TPU temperature resistance under actual usage conditions.

It’s important to note that TPU is never placed near the heater core or radiant heat zones. It is used only in non-heated airflow transition areas where flexibility, sealing reliability, and durability are required.

Why TPU Is Used in the First Place

TPU offers several advantages in vaporizer airflow systems:

Stable performance at moderate temperatures

Excellent sealing properties

Resistance to fatigue from repeated heating and cooling cycles

No brittle cracking over long-term use

In these applications, TPU outperforms many rigid plastics while remaining safely within thermal limits.

Responsible Temperature Use Still Matters

Although the system is designed with thermal margins, responsible use is still recommended.

For optimal safety and long-term durability:

Avoid exceeding 580°F during normal operation

Do not perform extended dry heating at maximum temperature

Allow natural cooling between sessions

These recommendations apply broadly across vaporizer platforms, not only to TPU-based designs.

Engineering Reality vs. Datasheet Numbers

Material datasheets often list melting points or maximum service temperatures under static laboratory conditions. Vaporizers, however, operate under dynamic airflow, rapid heat transfer, and extremely short exposure times.

This is why real-world engineering validation matters more than theoretical numbers.

Final Thoughts

Yes, heater temperatures can be high.

But no — TPU is not exposed to those temperatures in a properly designed airflow system.

Through intelligent vaporizer airflow design and multi-stage cooling, Pockety ensures that vapor reaching TPU components remains well within safe limits.

Understanding this difference is key to properly evaluating TPU safety in vaporizers.

Recommended Products:

-

15% OFF

$35.54 – $44.43Price range: $35.54 through $44.43$30.21 – $37.77Price range: $30.21 through $37.77JCVAP Recycler Bubbler Glass Tailor for Peak Pro

(7)Rated 4.71 out of 5 based on 7 customer ratings -

15% OFF

$22.39Original price was: $22.39.$19.03Current price is: $19.03.JCVAP New Shower Head Attachment Glass for peak and pro

(1)Rated 5.00 out of 5 based on 1 customer rating -

15% OFF

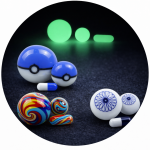

$28.99Original price was: $28.99.$24.64Current price is: $24.64.Hand Made Glass for Dab Rig Peak and Pro

(3)Rated 5.00 out of 5 based on 3 customer ratings - 15% OFF