At JCVAP, product evolution has always been driven by community feedback. Recently, Instagram user @divine3xistence shared a thoughtful suggestion that inspired a meaningful Puffco Peak Pro glass adapter upgrade for our Pockety ecosystem. Today, we’re excited to share a new design direction that improves safety, cleanliness, and usability.

This JCVAP Pockety Puffco Peak Pro Glass Adapter is designed to expand Pockety glass compatibility, allowing users to connect more third-party Puffco Peak Pro glass pieces with confidence.

Community Inspiration: Rethinking the Air Path

Based on community feedback, we redesigned the airflow system into a TPU silicone airpath adapter.

In the new structure, TPU acts as the outer support shell, providing a stable frame for the adapter, while a food-grade silicone vapor path is inserted inside. The removable silicone tube is rated safe up to 200°C, ensuring clean and hygienic vapor delivery.

This design dramatically reduces vapor contact with TPU while improving long-term durability. The removable structure also makes daily maintenance easier for users who care about hygiene and safety.

Hybrid Design: Cleaner, Safer, and More Flexible

This upgraded Puffco Peak Pro glass adapter upgrade provides multiple advantages:

Removable food-grade silicone vapor path for easy cleaning

Hybrid TPU silicone airpath adapter structure

Expanded Pockety glass compatibility

Lower production cost through 3D printed vaporizer accessories

Rapid iteration for future design improvements

As a result, this JCVAP Pockety Puffco Peak Pro Glass Adapter will support a wider range of glass designs in the future.

Currently, we have completed engineering drawings and feasibility validation. Prototype testing will be finished in 1–2 days before final release.

Why Not Make the Entire Adapter From Silicone?

Some customers ask why we do not fully rely on silicone.

Traditional silicone injection molding struggles to produce the complex curved geometry required by this TPU silicone airpath adapter. Mold costs are high, production cycles are long, and minimum order quantities often exceed 3,000 units.

Investing heavily in mold tooling for small-batch 3D printed vaporizer accessories would limit resources better spent on core product innovation.

Why 3D-Printed TPU Is the Best Solution Right Now

By adopting 3D printed vaporizer accessories, we achieve:

Low-cost rapid prototyping

Flexible material and color options

Fast iteration for community-driven design

Stable structure for Pockety glass compatibility

While 3D-printed TPU still has minor surface limitations, technology continues to improve quickly. We believe 3D printing will soon become mainstream in high-performance vaporizer accessory production.

The Future of Pockety Accessories

This JCVAP Pockety Puffco Peak Pro Glass Adapter Upgrade represents a new approach to combining TPU silicone airpath adapter engineering with food-grade silicone vapor path hygiene solutions.

Moving forward, JCVAP will continue expanding Pockety glass compatibility through modular 3D printed vaporizer accessories, giving users more choices, faster updates, and healthier vapor paths.

Prototype testing is underway — product release is coming very soon.

Special thanks again to @divine3xistence — innovation starts from community ideas.

JCVAP Pockety Puffco Peak Pro Glass Adapter Upgrade – TPU + Silicone Airpath Design

At JCVAP, product evolution has always been driven by community feedback. Recently, Instagram user @divine3xistence shared a thoughtful suggestion that inspired a meaningful Puffco Peak Pro glass adapter upgrade...

TPU Safety in Vaporizers: Why TPU Is Safe in JCVAP Pockety’s Airflow System

Discussions about material safety in vaporizers are important — especially when high operating temperatures are involved. Recently, a user raised a thoughtful concern about TPU safety in vaporizers, questioning...

Puffco Peak Pro Glass Adapter for JCVAP Pockety: Can It Use Peak or Peak Pro Glass

What Is the Puffco Peak Pro Glass Adapter for JCVAP Pockety? This adapter is designed to allow Puffco Peak and Puffco Peak Pro glass attachments to be used on...

Recommended Products:

-

15% OFF

$35.54 – $44.43Price range: $35.54 through $44.43$30.21 – $37.77Price range: $30.21 through $37.77JCVAP Recycler Bubbler Glass Tailor for Peak Pro

(7)Rated 4.71 out of 5 based on 7 customer ratings -

15% OFF

$22.39Original price was: $22.39.$19.03Current price is: $19.03.JCVAP New Shower Head Attachment Glass for peak and pro

(1)Rated 5.00 out of 5 based on 1 customer rating -

15% OFF

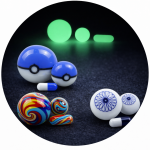

$28.99Original price was: $28.99.$24.64Current price is: $24.64.Hand Made Glass for Dab Rig Peak and Pro

(3)Rated 5.00 out of 5 based on 3 customer ratings - 15% OFF